China is currently dominating the supply of rare earth elements needed in many high tech products. Outside of China most advanced development projects targeting REE mining are in North America and Australia. In Europe Tasman Metals is currently leading activities in establishing a European REE supply chain.

The Norra Kärr project

On May 21st 2013

Tasman Metals Ltd (TSX.V : TSM; Frankfurt : T61; NYSE-MKT: TAS) reached a significant milestone. It was granted mining lease for it's flagship

Norra Kärr heavy rare earth element (REE) project. The project is closing the midpoint in Tasman's own roadmap showing timeline from discovery to production. If all goes as planned the mine construction could start in late 2014 provided that they get extraction permit and the mine is found to be feasible. Production could start earliest in 2016 according to the roadmap that can be found from

company presentation (slide #28 in May 2013 version).

The Norra Kärr project is located in southern Sweden, 15km north/north-east of the township of Gränna and 300km south-west of the capital Stockholm. It is

NI 43-101 compliant resource together with Olserum REE deposit also in southern Sweden. Technical report for Olserum was published recently while for Norra Kärr Tasman has completed both Technical report and preliminary economic assessment (PEA) [

reports].

NI 43-101 Compliant Mineral Resource Estimate (March 2012); Norra Kärr

Approximately 50% of REE resources at Norra Kärr can be considered heavy REE. Preliminary economic assessment estimated Norra Kärr project net present value at 1,5 billion USD (Base case; 10% discount, REO basket price $51/kg). The deposit remains "open at depth" which basically means that there could be more economically viable mineralized ore deeper under the ground. Mine life is estimated at least 40 years.

Mineral resources vs. Ore Reserves

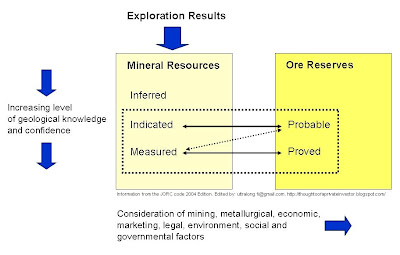

Mineral resources that are not mineral reserves do not have demonstrated economic viability. For relationship between mineral resources (inferred, indicated, measured) and ore reserves, please check the picture below as well as

wikipedia entry for mineral resource classification.

About Rare Earth Elements

Rare earth elements have geochemical properties that make them typically dispersed and not often found in concentrated and economically exploitable forms [

Wikipedia]. These metals are used in many hi-tech devices. In particular, rare earth elements are used in clean energy applications such as wind turbines, electric vehicles, photovoltaic cells and energy-efficient fluorescent lighting. Clean energy technologies currently constitute only about 20 percent of global consumption of critical materials. However, their share of total consumption is expected to grow as the use of these clean energy technologies is expected to grow rapidly.

The rare-earth elements (REE) are naturally occurring non-toxic materials, whose unique properties make them essential to emerging technologies that contribute to environmental, energy efficiency and health solutions. Examples of use of REEs [source:

Tasman Metals]:

- A typical hybrid vehicle contains approximately 28 kg of REE

- Large wind turbine-generators units require 2 tonnes of high strength magnets, which contain approximately 30% REE (i.e. 600 kg or REE per generator)

- Catalytic converters that transform the primary pollutants in engine exhaust gases into non-toxic compounds have REE coating

- REE phosphors in compact fluorescent lamps and LED lamps.

- Flat screen and plasma televisions

- Hard disk drives

- REE permanent magnets to generate high strength magnetic fields for MRI imaging. 700 kg of magnets are consumed in each MRI machine

Norra Kärr is source for Zirconium and the most critical rare earth elements

89% of revenue is expected to come from five metals:

- Dysprosium (Dy) 35%

- Zirconium (Zr) 20%

- Neodymium (Nd) 13%

- Yttrium (Y) 11%

- Terbium (Tb) 10%

Apart from

Zirconium (Zr) others are heavy rare earths which

U.S DOE estimated in 2010 to be both of

critical importance to clean energy economy and

having high supply risk between 2015-2025. Dysprosium (Dy) was deemed to me most critical of all.

Medium term Criticality Matric. Source: Critical Materials Strategy, U.S DOE, 2010

- Dysprosium (Heavy REE) is used in permanent magnets for wind turbines and vehicles with electric drive trains.

- Neodymium (Light REE) is used in batteries for vehicles with electric drive trains and in permanent magnets for wind turbines and vehicles with electric drive trains.

- Terbium (Heavy REE) and Yttrium (Heavy REE) are used in fluorescent lighting phosphors.

Pros and Cons for Norra Kärr

+ Contains the most critical REEs

+ EU focus (as far as I can tell this is the best shot at EU securing own REE source)

+ very low in radioactive metals compared to most other REE deposits

+ very well serviced by local infrastructure

+ open pit mine and ore body starts near surface

- Competing HREE mines coming online elsewhere outside of China might fill the same supply space (subject to separate article)

- Tasman Metals is a very small company (junior resource company) with just $7 in cash (May 2013) so it will need help from partners in the project both technically and financially

- Risks in permitting and feasibility of the mine (as with any mine at this stage)

Key financials and facts from PEA:

- Market cap of Tasman Metals: 42,5 million USD (June 9th 2013; source: Google Finance NYSEMKT:TAS)

- Norra Kärr project net present value at 1,5 billion USD (Base case; 10% discount, REO basket price $51/kg).

- Initial capital expenditures of $290 million (includes contingency of $66.8 million or 30%)

- $5.3 Billion in revenue over the first 20 years and $10.9 billion over the 40 year life of mine

- Average annual operating expenses of $74.3 million or $10.93 per kg of mixed TREO concentrate output

Full disclosure: Author owns shares of Tasman Metals.

Warning!: This is a very high risk investment!

As Wikipedia puts it (referring to

NI 43-101 "national instrument for the Standards of Disclosure for Mineral Projects within Canada"):

"The promulgation of a codified reporting scheme makes it more difficult for fraud to occur and reassures investors that the projects have been assessed in a scientific and professional manner. However, even properly and professionally investigated mineral deposits are not necessarily economic, nor does the presence of a NI 43-101-, JORC- or SAMREC and SAMVAL-compliant CPR or QPR necessarily mean that it is a good investment."